First Impregnation of Curved “Fusillo” Magnet Achieved with Upgraded UNICOS-based Automation System

The successful impregnation of the prototype curved magnet known as Fusillo marks an important step forward in magnet development and highlights the central role of industrial automation in supporting advanced manufacturing processes at CERN.

To meet the stringent requirements of the impregnation phase, essential for the mechanical integrity and electrical insulation of superconducting magnets, the Telstar impregnation machine underwent a complete industrial control system upgrade. The new system, based on the CERN’s UNICOS framework, combines industrial PLCs for real-time process control with the WinCC OA SCADA platform, offering operators an intuitive interface for monitoring, diagnostics and command execution. This architecture mirrors the standardized control approach adopted in other major CERN infrastructures such as cryogenics, gas distribution, and cooling systems.

It fosters interoperability, simplifies maintenance, and ensures long-term sustainability of control assets. Operational ergonomics were significantly improved: the new unified interface provides clear process visibility, integrated alarms, and easy access to real-time and historical data, enabling precise control and informed decision-making. Crucially, the new control system made it possible to run the impregnation process automatically, replacing a previously manual and intervention-heavy operation. The flexibility of the UNICOS-based platform allowed the control logic to be tailored to the specific needs of the process. The result is a robust, maintainable, and adaptable control system aligned with CERN-wide standards.

This achievement was made possible through a close collaboration between the TE-MSC and BE-ICS groups, who brought together domain expertise and control engineering know-how.

The upgrade of the Telstar machine is part of a broader initiative to modernize equipment in Building 927 magnet workshop, where other systems, such as the curing press, have also been successfully integrated into this standardized control landscape.

With the first Fusillo impregnation successfully completed under this modern automation framework, the revamped system has demonstrated its value as a robust and maintainable platform ready to support future magnet development activities.

Figure 1 – Telstar impregnation machine and the project team involved

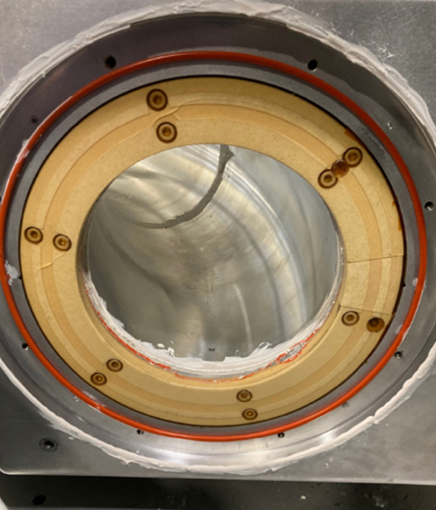

Figure 2 – Fusillo impregnation