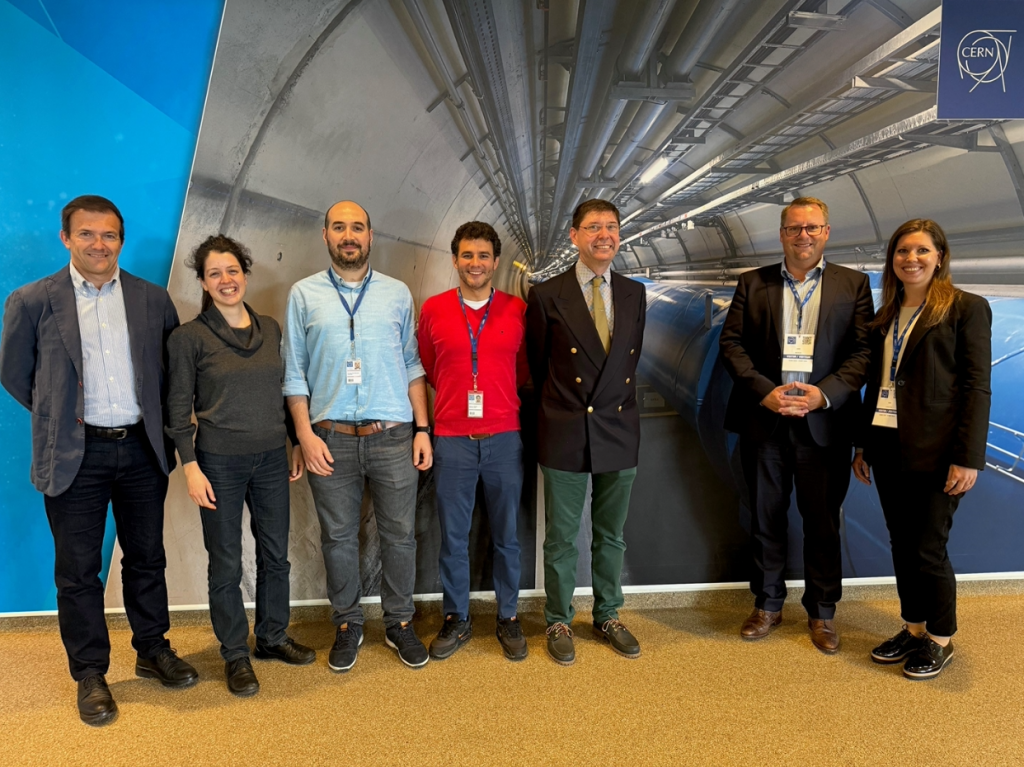

Rolf Kind and CERN establish strategic cooperation in fusion technology research

Team members from CERN and Rolf Kind GmbH meet at CERN – collaboration in action.

A dream of mankind… unlimited energy without harming the environment. The team of Rolf Kind GmbH,

based in the small town of Lindlar, around 40 km east of Cologne / Germany, is working hard every day to

make this dream come true in the hopefully not too distant future. “Our components will help to ignite a

huge fire that has never been seen before, and our collaboration with CERN plays a crucial role in this

process”, says Markus Kind, Commercial Director and one of two shareholders in the family business.

The fire refers to the last primary energy source that is known but not yet usable: nuclear fusion, the fusion

of nuclei. Atoms are to be shot together with enormous forces in order to generate much more energy than

that needed to produce the collisions. The power of the sun and stars, as the physicists say. Because in the

sun, many billions of such nuclei fuse every second, releasing enormous amounts of heat in the process.

There are high hopes for nuclear fusion. Supporters speak of a safe and inexhaustible source of energy that

does not damage the environment. The fuel used in fusion, usually isotopes of hydrogen, does not release

any greenhouse gases. This will be an advantage over fossil fuels.

It is clear that the demand for electricity will grow enormously, not only in other regions of the world, but

also as a result of the climate change. Renewable energies alone will not be able to meet this demand in the future. And unlike nuclear fission with uranium, for example, nuclear fusion produces hardly any radioactive waste.

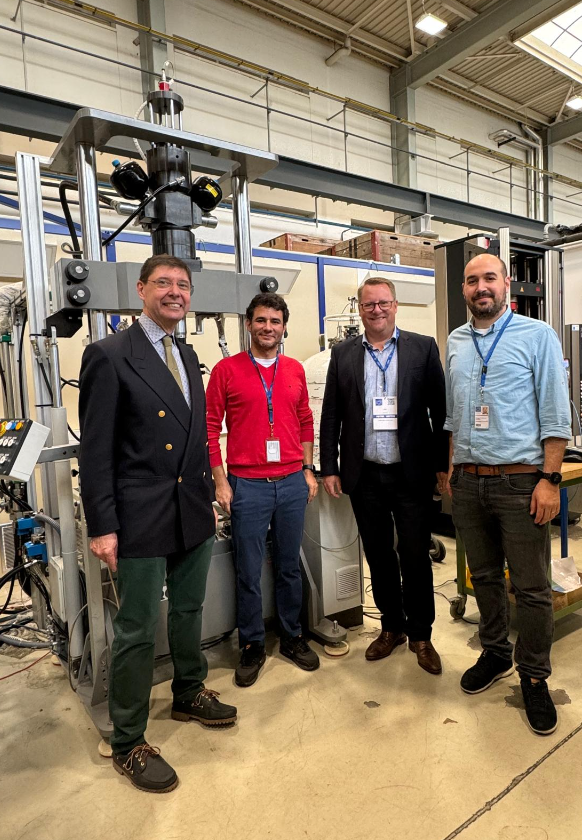

Stefano Sgobba’s team with Markus Kind in the cryogenic lab.

Markus Kind with a large stainless steel forging for a fusion machine magnet production

Fusion research is likely to create a whole new industry for the construction and operation of the power plants of

tomorrow. Start-ups, spin-offs of research institutes and industrial companies are currently developing prototypes and collecting money from investors. In addition to the best-known project, the ITER fusion research reactor in Cadarache in the south of France, there are around 40 fusion projects worldwide, mainly in the USA, Germany, Japan and China. Billions have already been invested.

For more than two decades, Rolf Kind GmbH has been supplying complex and heavy-duty forgings that will

help control the fusion fire, “plasma” as the experts call it, providing the metallic structure around the

powerful magnets. Over the years, the company has supplied more than 7,000 tons of stainless-steel

components for fusion projects all over the world.

“Fusion technology has the potenHal to become a real game changer and transform our planet for good”,

explains Markus Kind. “If we succeed in bringing this technology to market maturity, we will have a safe,

inexhausHble and reliable source of energy.” However, the technical challenges are not easy. The forces

experienced by the components in future fusion power plants will be enormous. To address these

challenges, the company has been working with experts from CERN for more than a year to test whether

new stainless-steel grades can withstand these extreme loads. This collaboraHon has now been extended

for another two years to test further candidate materials.

CERN is one of the largest and most renowned insHtutes for basic research in fundamental physics in the

world. Here, researchers search for the fundamental laws of the universe. To design, build and maintain the

infrastructure needed to perform its unique experiments, CERN has a number of the world’s best experts in

the field of materials science. The stainless steel produced by Rolf Kind GmbH can be tested at the

laboratories at CERN at temperatures as low as 4K or -269°C. The superconducHng magnets of the fusion

power plants will later work with liquid helium at precisely this temperature.

“Our collaboraHon with CERN means working with one of the world’s most modern laboratories alongside

experts with a wealth of experHse to find the right steel for the requirements of the fusion power plants of

tomorrow,” explains Markus Kind. “We have the technical experHse in material selecHon and forging

technology and at CERN the material can be tested exactly according to our specifications.”

“Mechanical characterization at cryogenic temperatures has been essential for the construction of the Large

Hadron Collider (LHC). A large amount of high strength structural materials were qualified through

thousands of tests at cryogenic temperature”, says Stefano Sgobba, head of the Materials, Metrology and

Non-Destructive Testing section of the Mechanical and Materials Engineering group at CERN.

“We are now thrilled that these unique facilities and know-how developed over several decades can

contribute, together with Rolf Kind’s expertise in advanced forging technologies, to the future of such a

promising energy source as nuclear fusion”, says Ignacio Aviles Santillana, responsible of the cryogenic

mechanical testing activity of the section.

Rolf Kind GmbH has thus built up a great deal of expertise in recent years. “I believe we can call ourselves

justifiably as one of the hidden champions in this field. In the field of highly stressed forgings for fusion

machines, we are highly specialized and significantly close to our customers. We are constantly developing

our products in line with our customers’ requirements – and at an international level”, says Markus Kind.

The German government has also recognized the potential of nuclear fusion. It plans to invest one billion

euros in fusion research in the coming years, creating the basis for a fusion ecosystem in the industry.

“Fusion is a huge opportunity to solve all our energy problems”, said Research Minister Befna Stark-

Watzinger last summer.

The fact that the employees of Rolf Kind GmbH are also burning for the fusion fire is evident. Mankind’s

dream of inexhaustible energy – marketable fusion reactors for a stable, environmentally friendly and

affordable energy supply – can become reality with forgings from Rolf Kind GmbH in Lindlar. They will

definitely be needed.